eFlesh can be fabricated with readily available components - TPU filament, a hobbyist 3D printer, off-the-shelf magnets and a magnetometer circuit board. While 3D prints vary in duration based on the volume of the sensorized part, the active fabrication involvement of the user is under a minute!.

Abstract

If human experience is any guide, operating effectively in unstructured environments—such as homes and offices—requires robots to sense the forces they apply during physical interaction. Yet, the lack of a versatile, accessible, and easily customizable tactile sensor has led to fragmented, sensor-specific solutions in general-purpose robotic manipulation—and in many cases, to force-unaware, sensorless approaches.

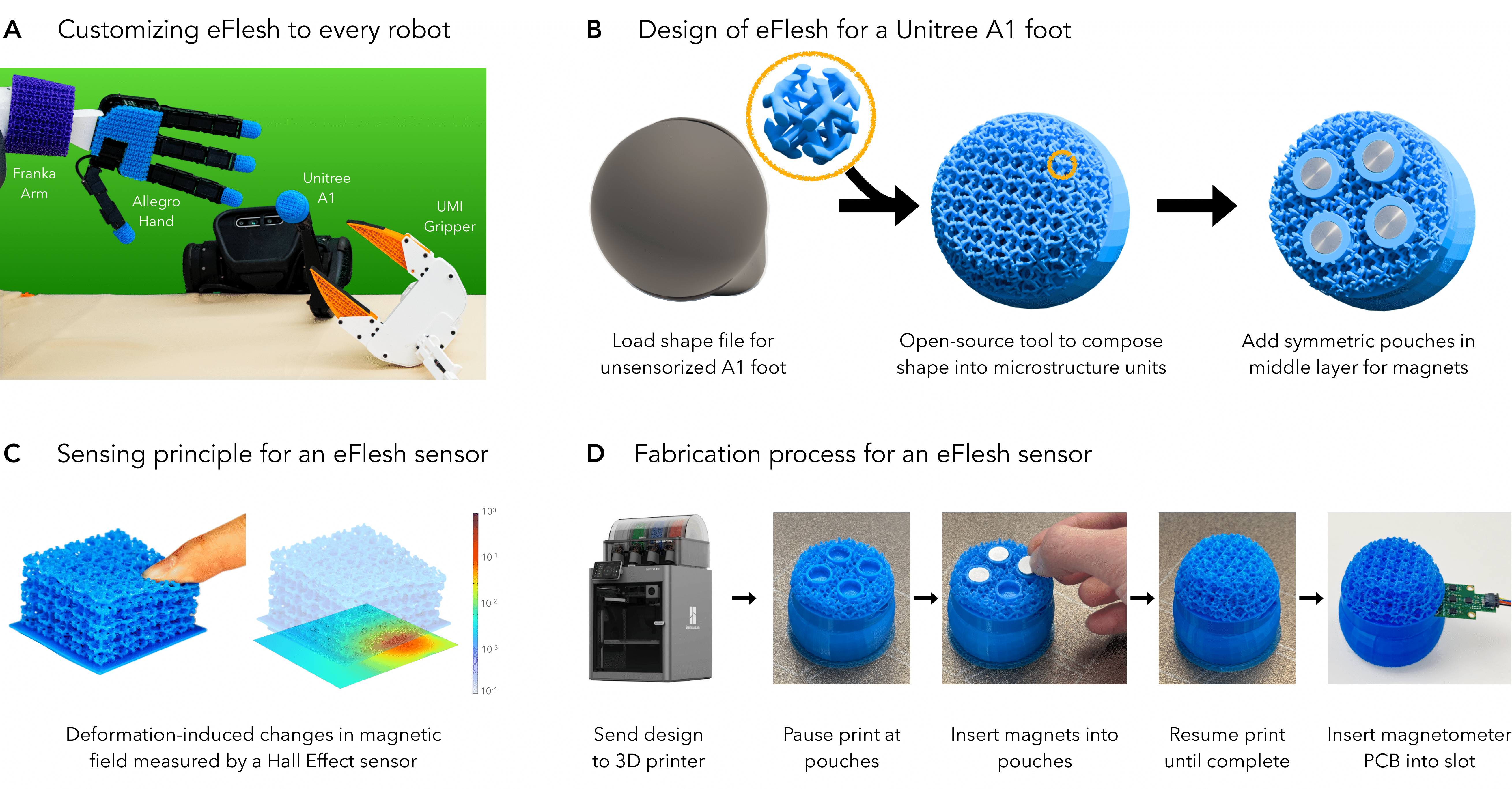

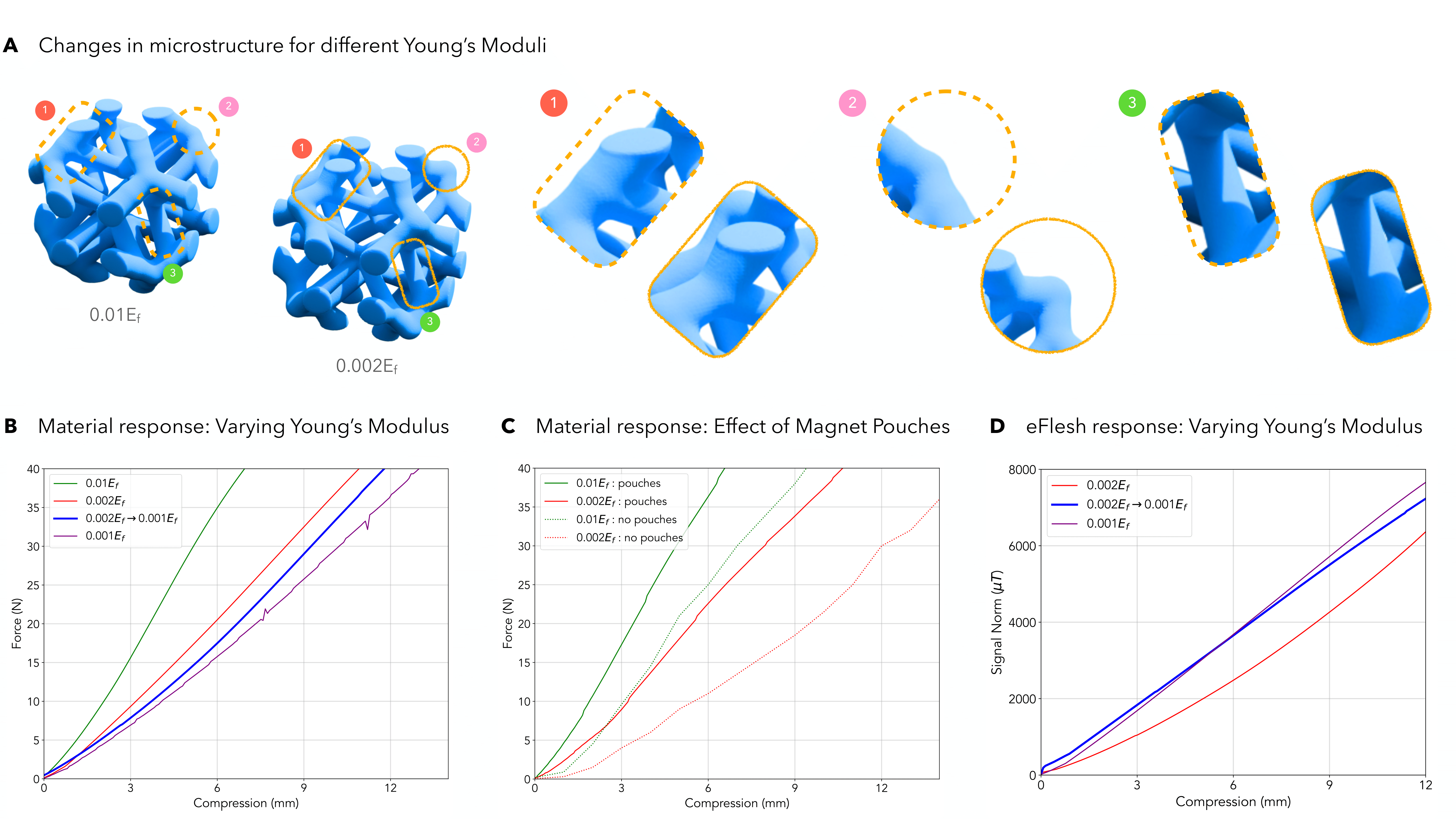

With eFlesh, we aim to bridge this gap by introducing a magnetic tactile sensor that is low-cost, easy to fabricate, and highly customizable. Building an eFlesh sensor requires only four components: a hobbyist 3D printer, off-the-shelf magnets (costing less than $5), a simple CAD model of the desired shape, and a magnetometer circuit board. The sensor is constructed from tiled, parameterized cut-cell microstructures, which allow for tuning both the sensor's geometry and its mechanical response. To support broad accessibility, we provide an open-source design tool that converts simple convex OBJ/STL files into 3D-printable STLs ready for fabrication. This modular design framework enables users to create application-specific sensors for robot hands, grippers, quadruped feet, and more, and to easily adjust sensitivity to meet the demands of different tasks.

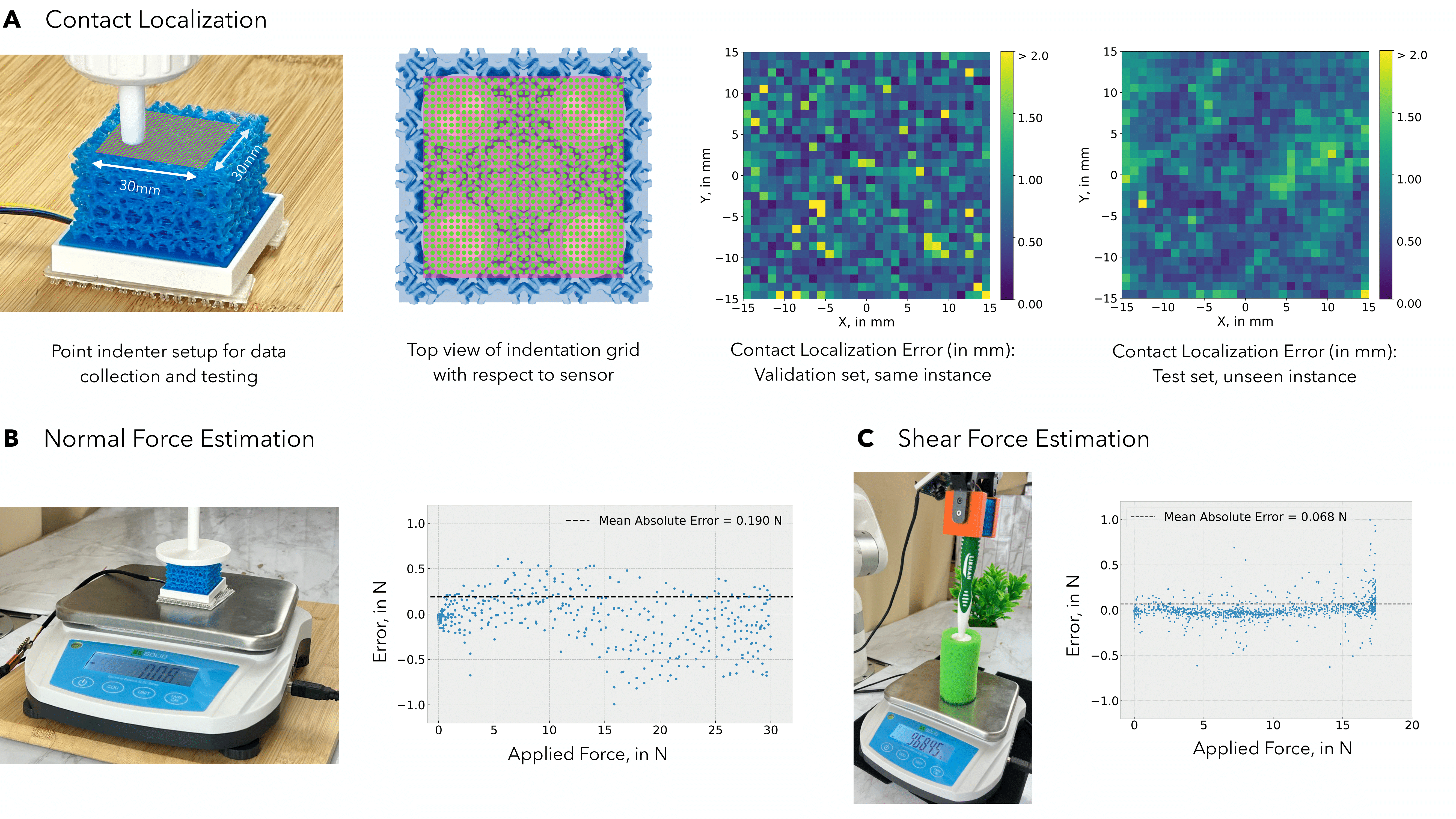

Our sensor characterization experiments demonstrate the precision of eFlesh: contact localization accuracy of 0.5 mm, with force prediction errors of 0.27 N along the z-axis and 0.12 N in the x/y-plane. We also present a learning-based slip detection model that generalizes to unseen objects with 95% accuracy, and visuotactile control policies that improve manipulation performance by 40% over vision-only baselines -- achieving 90% success rate for a number of precise tasks like plug insertion and credit card swiping, that require sub-mm accuracy for successful completion. All design files, code, trained models, and the CAD-to-eFlesh STL conversion tool are openly available to promote accessibility and encourage widespread adoption.

We introduce eFlesh, a touch sensor geared towards democratizing tactile sensing. eFlesh is highly customizable, and easy to fabricate. It can be adapted to robot parts of varying form-factors with a tool to also tune sensor response.

eFlesh is 3D printed with magnets embedded in the middle layer. Based on the chosen mechanical properties, the magnets displace in response to contact forces, which are measured by a separated magnetometer underneath.

Fabrication Process

Visuo-Tactile Policy Learning

Autonomous tasks requiring sub-mm precision, demonstrates the robustness of eFlesh in robot policy learning. These policies are trained using Visuo-Skin

Card Swiping

Plug Insertion

USB Insertion

White-Board Erasing

Slip Detection

eFlesh can be used to detect slip reliably. A simple linear classifier achieves 95% accuracy on a diverse held-out test set of objects of varying shapes, textures and weights.

eFlesh models to try out!

Characterization

Experimental Results

BibTeX

If you find eFlesh useful for your work, please cite as:

@article{pattabiraman2025eflesh,

title={eFlesh: Highly customizable Magnetic Touch Sensing using Cut-Cell Microstructures},

author={Venkatesh Pattabiraman and Zizhou Huang and Daniele Panozzo and Denis Zorin and Lerrel Pinto and Raunaq Bhirangi},

year={2025},

eprint={2506.09994},

archivePrefix={arXiv},

primaryClass={cs.RO},

url={https://arxiv.org/abs/2506.09994},

}